Have you ever walked into a humming plant and guessed something was off before the alarms went off? I have. In one small shop, a single mis-set parameter on a motor controller cost the team nearly 12% more energy than expected, and no one noticed for weeks. The motor controller sat quietly, doing what it was told, while inefficiency crept in (a tiny slip, huge result). Where did the blind spot come from — bad setup, weak monitoring, or plain fatigue? Let’s peel back the layers and follow the clues to what really matters next.

Part 2 — Why common fixes miss the mark

Why do controllers keep underperforming?

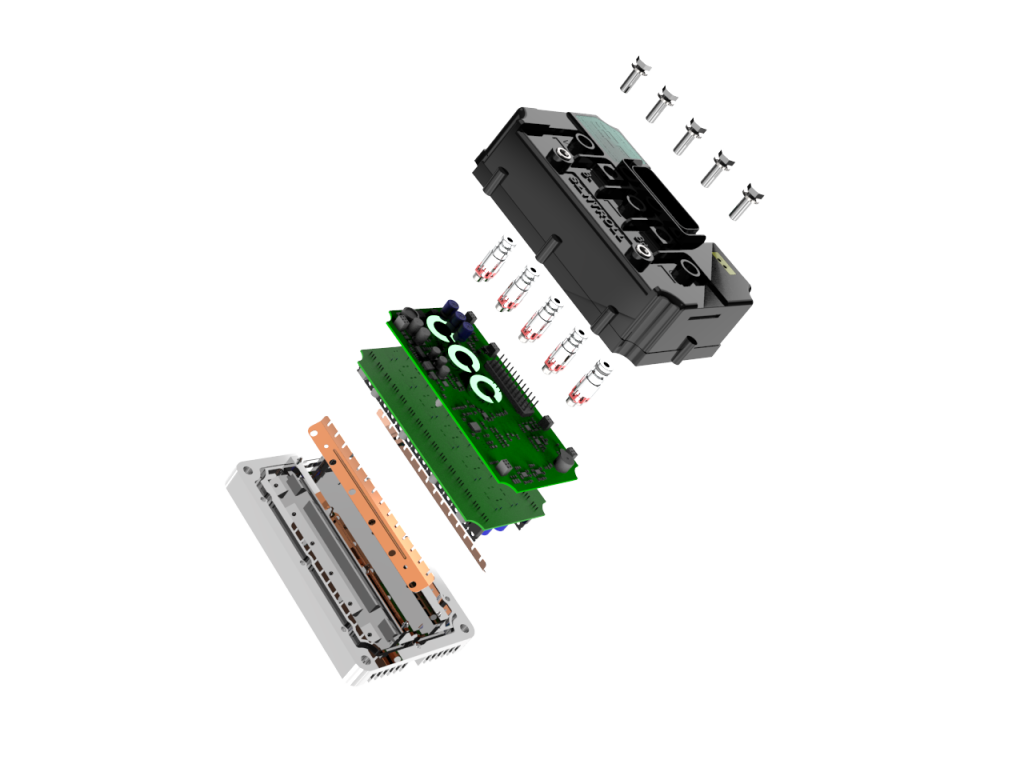

When I dig into issues, I often start with the obvious hardware: the ac electric motor controller. But the problem rarely sits only in the box. Too many teams chase a quick firmware update or swap a board and call it fixed. The deeper flaws are process gaps. For example, mismatched inverter sizing or wrong power converters can make a system run hot and brittle. PWM noise and poor filtering show up as jitter in torque and speed. Edge computing nodes can help, but only if the data they send is clean and timely. I say this because I’ve seen the same checklist items ignored across different sites. Look, it’s simpler than you think: tune it right, monitor it right, and don’t assume defaults are good enough.

Another common hidden pain is human hand-off. Operators inherit systems with undocumented tweaks. That lack of history makes troubleshooting slow. We lose hours chasing intermittent faults that are actually just control-loop mis-tuning. The truth: many “fixes” mask symptoms. You patch alarms, but you don’t fix control loop stability or thermal stress. That leaves equipment stressed and teams exhausted — funny how that works, right? Practical change requires baseline tests, clear notes, and a short feedback loop between operators and engineers. I prefer short, repeatable tests and simple dashboards that show PWM ripple, temperature trends, and harmonic current. Those three numbers tell a lot, fast.

Part 3 — Looking forward: new rules and three practical metrics

What’s Next for motors and control?

We’re shifting from firefighting to foresight. I expect future gains to come from better sensor fusion and smarter telemetry. When you combine vibration signals, current waveform shape, and temperature trends, you get a much earlier warning of trouble. In practice, this means pairing local control with cloud-aware analytics — the kind of hybrid approach that lets you run fast loops at the inverter while sending summaries to higher-level systems. For those planning upgrades, consider systems that support secure OTA updates, robust filtering for PWM, and flexible power converter interfaces. These features make the whole stack more resilient. And yes — adoption takes patience and cross-team work.

To make choices clearer, here are three quick evaluation metrics I always use when comparing motor control solutions: 1) Response fidelity — how accurately does the controller follow setpoints under load swings? 2) Diagnostics richness — does it provide actionable signals (temperature, harmonic content, PWM ripple) rather than vague alarms? 3) Integration flexibility — can it talk to PLCs, edge computing nodes, and cloud tools without brittle custom hooks? Use these metrics as a simple sieve. They help you separate shiny features from real value. I’ve applied them in plants that cut downtime and trimmed energy use by measurable amounts. If you want a practical place to start, check modern motor control solutions that expose these signals and make life easier for your operators — Santroll has offerings that align with these ideas. — small steps, big difference.

In the end, I speak from hands-on fixes and long nights tracing faults back to a mis-set parameter. We can build more reliable systems by demanding clearer diagnostics, resisting default settings, and favoring flexible integration. I’ll keep testing, learning, and sharing what works — because a quieter plant is a better plant, and that matters to people and budgets alike. Santroll